TECH

What is the Potential for Efficiency Gains with Offline Robot Programming Software?

Robotic programming: Recent advances and future trends. One solution to this problem is the development of offline robot programming software, which would enable the robot programs to be designed, tested, and optimized in a simulated environment before being implemented in the actual hardware. This approach has the potential to enhance the efficiency of robotic automation in many ways. In this article, we will discuss why robotic offline programming is beneficial and how it could increase efficiency.

-

Offline Robot Programming Software

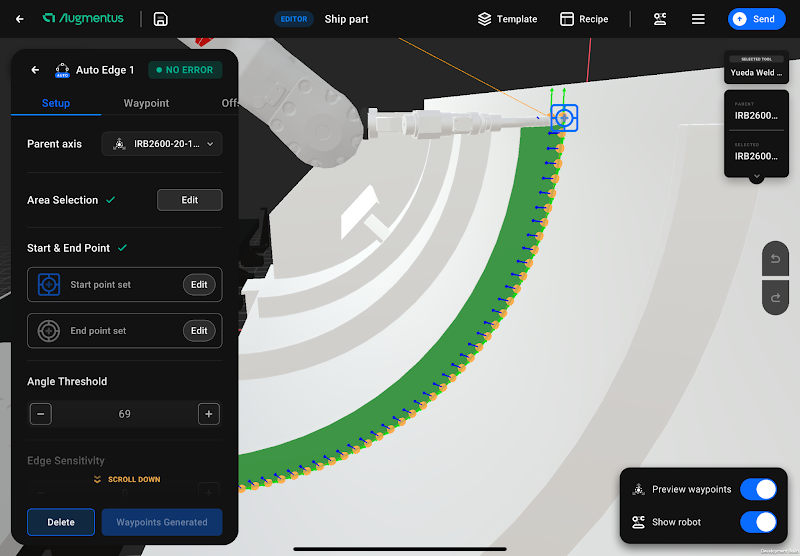

Without a physical robot, robotic tasks can be programmed and simulated on a computer using offline programming. Using precise models of the robots, workpieces, and workstations, this software helps engineers and programmers create and test robotic programs in a virtual setting. The virtual environment can mimic real-world conditions, and thus, it is possible to test, optimize, and debug programs before the programs are implemented in the physical robots. This method is different from traditional online programming in which the programming and testing are done on the robot directly.

-

Reduced Downtime

Offline robotic programming also provides another significant efficiency improvement in the form of reduced downtime. The conventional web-based robots need to be taken offline for programming and testing; hence, production stops. This enables such tasks to be performed without having to interrupt production, as programs can be developed and tested virtually. This results in higher reliability and efficiency as the robots can work while new programs are being loaded. This reduction in downtime translates to significant cost and efficiency benefits for industries that rely on every minute of production.

-

Enhanced Program Accuracy and Optimization

Manual programming tools facilitate the development of specific, high-quality robot programs for the optimal generation of paths and activities. The virtual environment is used to try and perfect programs and eliminate errors and inefficiencies prior to deployment. This level of optimization is quite challenging to achieve using traditional online programming methods due to the real-time nature of the work and the limited time available for testing. Offline programming enables manufacturers to increase the quality and effectiveness of robotic systems.

-

Improved Flexibility and Adaptability

Offline robotic programming is more agile and can address changes in production demands or work environments. New programs or changes in existing programs can be quickly developed and tested without having to be physically present in the robots. This is especially useful in the fast-paced world of manufacturing, which requires a high degree of responsiveness to new products or processes. The ability to test various situations and processes also enables organizations to be more efficient in planning and resource management.

-

Training and Skill Development

One of the strengths of offline robot programming software is its application as a training tool for engineers and programmers. The virtual environment allows robot programming to be practiced in a risk-free environment with no risks of damaging the equipment or interfering with the production process. It also increases programming abilities and self-confidence, which in turn enhances programming performances in the future. Furthermore, the fact that training can be done offline means that personnel are well-equipped to apply and control robotic systems when necessary.

-

Cost Savings and Return on Investment

Offline robotic programming’s efficiency benefits enable manufacturers to reap cost savings and higher ROI. It also reduces downtime, optimizes programs, and increases flexibility, resulting in lower operational costs and higher productivity. In addition, the fact that they can do their programming and testing without having to buy a physical robot means that they will not have to maintain their robots as often. All these make offline robotic programming an effective solution for modern manufacturing and automation.

Conclusion

The concept of offline robot programming software presents a great opportunity for efficiency improvement in automation. It reduces downtime, enhances program accuracy, improves flexibility, supports training, provides cost savings, and allows program development and testing in a virtual environment. The increase in the complexity and demanding nature of the manufacturing processes will require the adoption of offline robotic programming to achieve efficiency and productivity in robotic operations.

Read More News at: TodayFirstMagazine