BUSINESS

Innovations in Geothermal Drilling Rig Technology

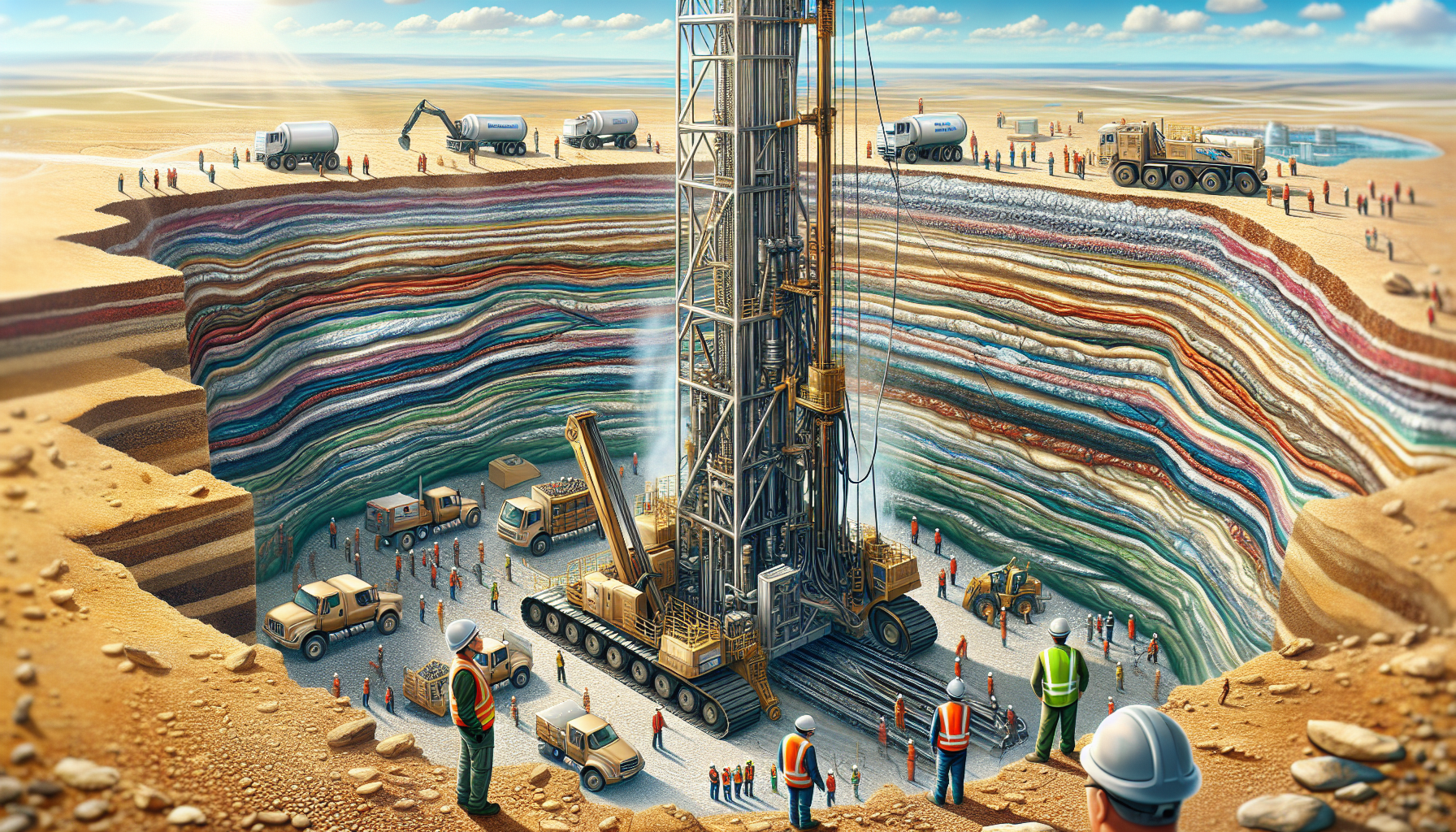

Introduction to Geothermal Drilling Rigs

Geothermal drilling rigs are essential tools in the exploration and development of geothermal energy resources. These specialised rigs are designed to drill deep into the Earth’s crust, reaching hot rock formations that can be harnessed for clean, renewable energy production. In recent years, significant advancements have been made in geothermal drilling rig technology, leading to increased efficiency, reduced costs, and improved environmental sustainability.

The Importance of Geothermal Energy

Geothermal energy is a promising alternative to fossil fuels, offering a clean and renewable source of power. By tapping into the Earth’s natural heat, geothermal power plants can generate electricity with minimal greenhouse gas emissions. Additionally, geothermal energy provides a reliable baseload power source, as it is not dependent on weather conditions like wind or solar energy.

Challenges in Geothermal Drilling

Despite the numerous benefits of geothermal energy, drilling for geothermal resources presents several challenges. These challenges include:

- High temperatures and pressures encountered at great depths

- Hard, abrasive rock formations that can damage drilling equipment

- Corrosive geothermal fluids that can degrade drilling components

- High costs associated with deep drilling operations

Advancements in Drilling Rig Design

To address these challenges, manufacturers have developed innovative geothermal drilling rig designs. These advancements include:

Automated Pipe Handling Systems

Automated pipe handling systems streamline the drilling process by reducing the need for manual labour. These systems use robotic arms and conveyor belts to move drill pipes from storage racks to the drill floor, improving safety and efficiency.

Top Drives with Higher Torque Capacity

Modern top drives feature higher torque capacities, allowing them to drill through harder rock formations with greater ease. These top drives also incorporate advanced control systems that optimise drilling parameters for specific geologic conditions.

Improved Mud Pumps and Circulation Systems

High-performance mud pumps and circulation systems are crucial for maintaining wellbore stability and removing drill cuttings. Newer designs feature enhanced durability and increased flow rates, enabling more efficient drilling operations.

Innovations in Drill Bit Technology

Drill bit technology has also seen significant advancements in recent years. These innovations include:

Polycrystalline Diamond Compact (PDC) Bits

PDC bits feature a layer of synthetic diamond material bonded to a tungsten carbide substrate. These bits offer superior wear resistance and faster penetration rates compared to traditional tricone bits.

Hybrid Bits

Hybrid bits combine the best features of PDC and tricone bits, providing a versatile solution for varying rock formations. These bits can adapt to changing drilling conditions, reducing the need for frequent bit changes.

Self-Adjusting Bits

Self-adjusting bits feature movable cutting elements that automatically adjust to maintain optimal contact with the rock face. This technology helps to extend bit life and improve drilling efficiency.

Advancements in Directional Drilling

Directional drilling techniques allow geothermal wells to be drilled at angles, reaching target formations that are not directly beneath the drill site. Recent advancements in directional drilling include:

Rotary Steerable Systems (RSS)

RSS technology enables precise control of the drill bit’s trajectory, allowing for more accurate and efficient directional drilling. These systems use a combination of onboard sensors and computer algorithms to continuously adjust the bit’s orientation.

Measurement While Drilling (MWD) Tools

MWD tools provide real-time data on the well’s orientation, temperature, and pressure conditions. This information allows drilling engineers to make informed decisions and optimise the drilling process.

Innovations in Well Completion and Stimulation

Once a geothermal well has been drilled, it must be properly completed and stimulated to maximise its productivity. Recent innovations in this area include:

Advanced Casing and Cementing Techniques

High-temperature, corrosion-resistant casing materials and specialised cementing techniques ensure the long-term integrity of geothermal wells. These advancements help to prevent fluid loss and maintain productivity over time.

Multi-Stage Fracturing

Multi-stage fracturing techniques involve the creation of multiple hydraulic fractures along the length of the well. This approach increases the surface area available for heat exchange, enhancing the well’s overall productivity.

The Role of Data Analytics and Automation

Data analytics and automation play an increasingly important role in geothermal drilling operations. By collecting and analysing vast amounts of data from drilling sensors and other sources, operators can optimise drilling parameters, predict maintenance needs, and improve overall efficiency.

Real-Time Drilling Optimization

Real-time drilling optimization systems use advanced algorithms to continuously adjust drilling parameters based on incoming data. These systems can help to reduce drilling costs, minimise non-productive time, and extend equipment life.

Predictive Maintenance

Predictive maintenance techniques use machine learning algorithms to analyze sensor data and identify potential equipment failures before they occur. This approach allows operators to schedule maintenance proactively, reducing downtime and improving overall rig performance.

Environmental Considerations

As the demand for clean energy grows, geothermal drilling operations must prioritise environmental sustainability. Recent advancements in this area include:

Closed-Loop Drilling Fluid Systems

Closed-loop drilling fluid systems recirculate and reuse drilling fluids, minimising the amount of waste generated during drilling operations. These systems also reduce the risk of environmental contamination from fluid spills or leaks.

Noise and Emission Reduction Technologies

Modern geothermal drilling rigs incorporate noise and emission reduction technologies to minimise their environmental impact. These technologies include advanced mufflers, sound-absorbing materials, and high-efficiency engines that produce fewer greenhouse gas emissions.

Collaborations and Partnerships

Collaborations between industry, academia, and government organisations are crucial for driving innovation in geothermal drilling rig technology. These partnerships facilitate knowledge sharing, research and development, and the commercialization of new technologies.

Industry-Academia Collaborations

Partnerships between drilling rig manufacturers and universities enable the development of cutting-edge technologies and the training of the next generation of geothermal professionals.

Government Support and Initiatives

Government support, through funding, incentives, and favorable policies, is essential for the growth of the geothermal industry. Initiatives such as the U.S. Department of Energy’s Geothermal Technologies Office help to promote research, development, and deployment of advanced geothermal technologies.

The Future of Geothermal Drilling Rig Technology

As the world transitions towards a clean energy future, geothermal drilling rig technology will continue to evolve and improve. Some of the most promising areas for future development include:

Autonomous Drilling Systems

Fully autonomous drilling systems, powered by artificial intelligence and robotics, could revolutionize the geothermal drilling industry. These systems would be capable of operating with minimal human intervention, improving safety, efficiency, and consistency.

Advanced Materials and Coatings

The development of new, high-performance materials and coatings could significantly enhance the durability and performance of geothermal drilling equipment. These materials could include advanced composites, nanomaterials, and self-healing coatings that adapt to changing drilling conditions.

Enhanced Geothermal Systems (EGS)

EGS technology involves the creation of artificial geothermal reservoirs in hot, dry rock formations. Advancements in EGS drilling and stimulation techniques could greatly expand the potential for geothermal energy production worldwide.

Conclusion

Innovations in geothermal drilling rig technology are crucial for unlocking the vast potential of geothermal energy resources. By addressing the challenges associated with deep drilling operations, these advancements are paving the way for a cleaner, more sustainable energy future. As the demand for renewable energy grows, continued investment in research, development, and deployment of advanced geothermal drilling technologies will be essential for meeting the world’s energy needs while combating climate change.

Stay ahead of the curve with the freshest news updates by exploring TodayFirstMagazine!