Tech & Gadgets

Understanding PCB Assembly and Its Importance in the Electronics Industry

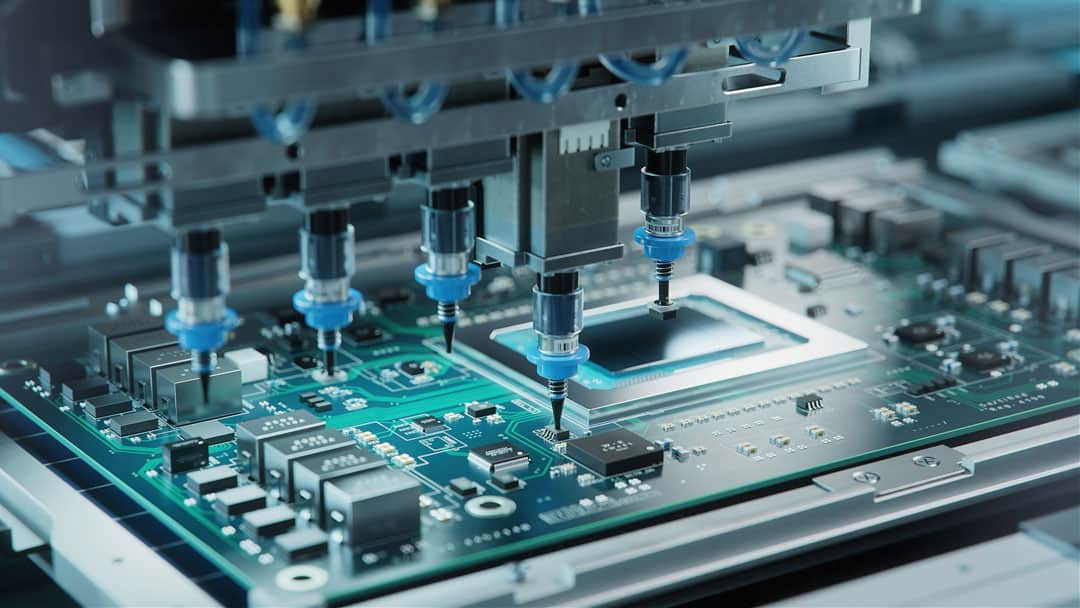

In the rapidly changing electronics industry Printed Circuit Boards (PCBs) are among the most essential components occupying the central stage in almost any new electronic gadgets that are designed. PCBs are now found in every sphere of life, from smartphones and laptops to medical equipment and aerospace systems because these boards are the key factors that make these products efficient and reliable. As you may already be aware, PCB assembly is a complex procedure that plays a crucial role within the electronics sector, and at Lion Circuits, we know this all too well.

PCB Assembly: A Vital Process

PCB assembly is the process by which active and passive components or electronic components are mounted and soldered to the structure of a printed circuit board. This is a complex process which requires several steps and each step has to be followed to the latter so as to guarantee the right functioning of the final end product. The assembly process normally involves aspects like preassembly of PCB, insertion of parts, soldering, and testing.

- Preparation: In fact, the PCB board is first cleaned prior to assembly to ensure that the surface is free from dust or dirt which if attached to the board can hinder the assembly process. This step is done in order to achieve as good a contact as possible surfaces for subsequent stages of the process, such as adhesion and electrical conductivity.

- Component Placement: After the PCB has been cleaned, or before the actual cleaning process the actual process of assembling the electronic components is done by placing these components on the specific pads or footprints on the board. This process can be fully or partly mechanised using SMT machines for high-value production or can be performed individually for development or for a small number of copies.

- Soldering: Once the components are in position, they can be soldered to the PCB or otherwise fastened in a manner designed to mechanically hold them in their intended locations on the circuit board. This is done through soldering, which makes a permanent connection both in the circulation of electricity and holding the components and the board together. Depending upon the complexity of the project, and specific operational demands it is subject to, there are such forms as wave soldering, reflow soldering, and hand soldering.

- Testing and Inspection: After the soldering process is over, the circuit board assembly is checked fully to guarantee that it is working effectively and is free from defects and is up to the required measures of production. This step is very important as it ensures that all the defects or any wrong docket of the PCB is detected before it is later built into the final product.

The Importance of PCB Assembly in the Electronics Industry

SMT assembly holds a significant position in the Electronics manufacturing industry, and it is very much indispensable. Following are the reasons why PCB assembly is crucial:

- Enabler of Compact and Complex Designs: The more advanced technology is getting in today’s world is evident from the facts that more and more components are being incorporated in the smaller and portable electronic devices. PCB assembly enshrines the provision of an outstanding method that organises and interconnects many electronics parts within a scaled-down area as well as the formulation of complex and greatly dense circuits.

- Reliability and Durability: Adhering to the right standards while assembling the PCBs prevents the failure of electronic devices and enhances durability. Soldering and interconnections should be done properly to ensure that there is no possibility of failure of any component and that there are no shorts or any other problems which may arise which affects the working and lifetime of that device.

- Scalability and Cost-Effectiveness: PCB assembly processes have the advantage of being highly flexible and can be easily modified to suit different production requirements; thus it can easily be adopted for either large-scale production or small-scale production. Efficient processes, reduced assembly line costs and innovation of other assembly lines low the expenses of manufacturing.

- Consistency and Quality Control: PCBA follows automated assembly lines that work hand in hand with quality checks for proper manufacturing and delivery of high-quality products. This consistency is important for stability purposes of the electronic devices in terms of reliability across units or batches.

- Enabling Technological Advancements: The electronics industry is on the constant-verge of developing new technologies, and again PCB assembly takes up a great part in system integration of these advancements to functioning devices. The key components which are at the heart of today’s electronic devices – bleeding-edge processors, intricate sensors, and smart connectivity solutions – are built onto PCBs and then assembled there.

As a leading electronics manufacturing company, Lion Circuits recognizes the value of PCB assembly in the electronics manufacturing industry. With the numerous resources in place, our team of experienced technicians is able to offer our customers top-notch PCB assembly services that can bear the challenges of today’s complex industries such as aerospace industries and even further down to defence industries, telecommunication and much more.

Staying Ahead the curve

This industry is undoubtedly in a constant state of dynamic flux and innovative electronics technologies, components, materials, and manufacturing techniques are continually being developed. It should also be understood that Lion Circuits continues to pursue the responsible management of technological advances by purchasing the best equipment on the market, training its employees, and partnering with key players in the field. Our striving for the improvement and development of new services puts us in the position to offer advanced PCB assembly services that help client to launch new products and technical innovations into the market more effectively. It may involve flexibility in changing component packaging methods, new types of soldering, using new methods and tools of testing and inspection, and many others – we stay focused on offering the best solutions.

Conclusion

Thus, PCB assembly can be seen as one of the critical factors in the electronics manufacturing industry due to its significance in meeting emerging market demands and delivering new electronic products to the customers. From smartphones, which are increasingly shrinking in size as components, as well as aerospace technologies, PCB assembly is a fundamental building block. We know the stake and complexity involved with the PCB assembly service and this is why Lion Circuits is committed to working tirelessly to achieving our customers’ goals. Ideally located with modern factories, highly trained SMT PCB assembly technologists, and our focus on quality and new technology, we are confident to meet all your PCB Assembly requirements from prototype to high production runs.

Let us begin this process of innovating and capture the current and future trends within the electronics sector. If you require any of the above services or have any other requirements in the production of your electronic products, we encourage you to consult with us today for suitable solutions to your needs on PCB assembly.

Stay ahead of the curve with the freshest news updates by exploring TodayFirstMagazine!