Tech & Gadgets

The Many Benefits of Mineral-Insulated Copper Cables

One fundamental component in electrical systems is insulated copper cables, as they play a major role in the transmission of electricity in a safe and efficient manner. These cables are insulated with various materials. Mineral insulated cables have proven to be a variable option for electrical systems that are installed in harsh conditions. They are a robust alternative to cables insulated with plastics. We will talk about all these cables in this blog, especially mineral-insulated cables.

What is an Insulated Copper Cable?

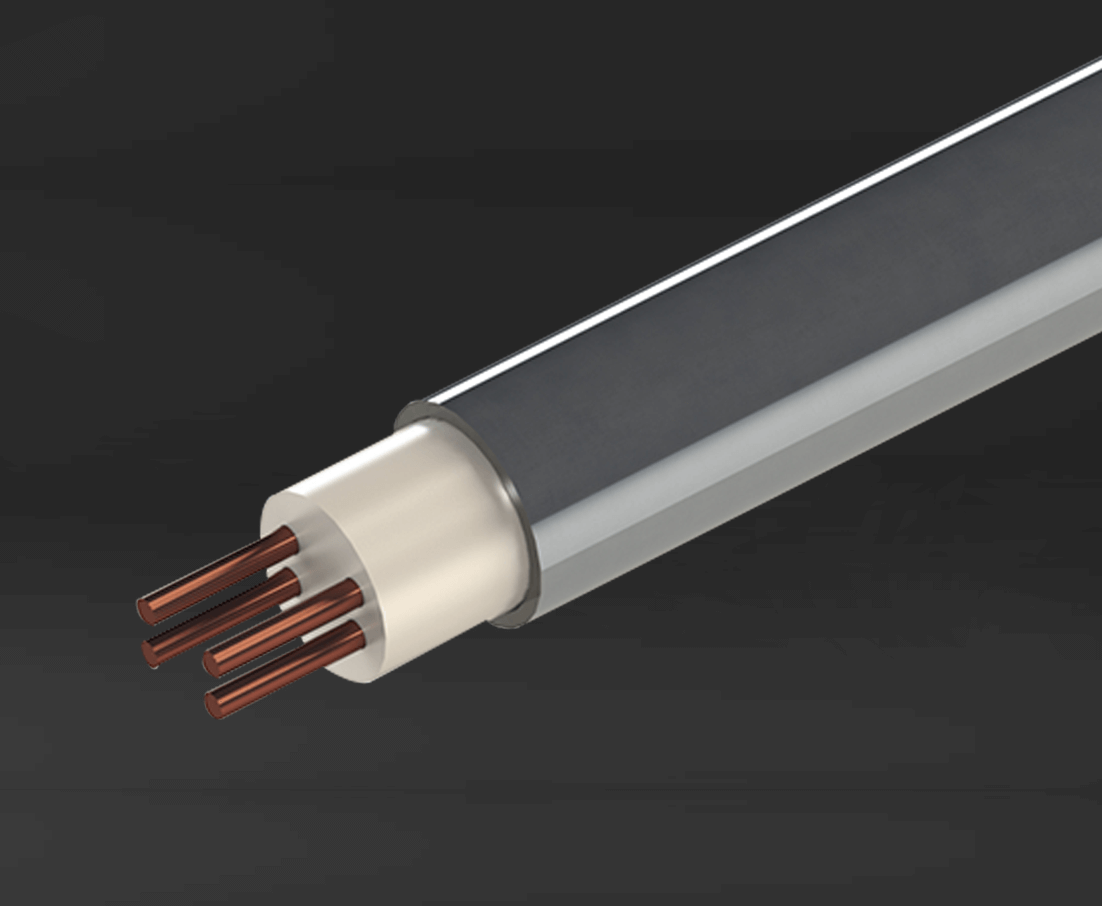

It is a type of electrical cable that has a copper wire covered with a layer of insulating material. This insulation protects the copper conductor from damage caused by environmental factors such as moisture, heat, or chemicals. It is also very helpful in preventing electric short circuits.

Features of Insulated Copper Cables

Copper cables are very well-known to people all over the world. They aren’t a commodity only known to people from the electrical industry. Discussed below are some features and factors that make these cables irreplaceable:

Conduction of Energy: The cable core is made of copper, and it is an excellent conductor of energy. It is the first choice for many electrical circuits because of the high conductivity it offers at such a low cost.

Insulated Outer Layer: These cables have an outer layer, which can be XLPE (cross-linked polyethylene), PVC (polyvinyl chloride), or Magnesium oxide. This layer of insulation is essential as it prevents the copper wire from coming into contact with any other conductors and causing electrical faults.

Protection from Outer Influences: The outer influences can affect the conducting wire and cause corrosion and damage. This can not only compromise the performance of the cable but also be a safety hazard for people in the vicinity of a cable.

Why is Mineral Insulated Copper Cable Considered Viable?

Mineral insulated copper cable is commonly called MI cable, and it is considered a viable option for a number of applications. There are many factors that make it a preferred choice in many industries. Let us talk about these factors in detail below:

Fireproof: MI cables are very resistant to fire and extreme temperatures. They do not lose their electrical performance or structural integrity when exposed to high temperatures or even fire. This is because of the mineral insulation that surrounds the copper conductor. The insulated layer is made of magnesium oxide, which is non-combustible and, therefore, can withstand temperatures much better than plastic insulated cables. In industrial facilities, buildings and tunnels where there is a high risk of fire or significant exposure to heat, these cables are highly preferred.

Mechanically Robust: Mineral insulation offers mechanical strength to these cables like no other. This helps improve the longevity of the cables and their resistance to physical damage. They can handle strain related to bedding, installation, or rough handling without any compromise on their performance.

Electrical Performance: Mineral insulation not only protects the cables from the external environment but also ensures the prevention of any kind of leakage from within. Mineral insulated copper cables are famous for being able to carry high voltage current without any risk of insulation breakdown.

Suitability for Multiple Applications: These cables are very versatile and compatible with many different applications. These applications can include industrial machinery, fire protection systems, power distribution, emergency lights, and any type of hazardous environment. Mineral-insulated copper cables can maintain their performance in harsh conditions, making them a perfect fit for both indoor and outdoor settings.

Adherence to Safety Compliances: These cables pass all the tests of safety compliances that are out there. They prove to be a viable option in industries where performance and safety standards are very high.

Reliable & Long-Lasting: The mineral insulation on MI cables proves to be a great barrier between the external environment and the cable. This sturdy outer layer helps the copper cable perform reliably in the long run. This quality also makes them long-lasting because they do not degrade very easily.

Conclusion:

Standard insulated cables and mineral insulated copper cables are both indispensable across industries and all for good reasons. They offer much needed conductivity and insulation along with a perfect balance among them. Mineral insulated cables offer protection against the outer environment against internal leakage, and they ensure compliance with safety standards. If you are looking for a robust insulated cable you should buy them from Tempsens. They have been industry leaders in thermal and cable products for decades, and you are definitely in good hands with them.

Stay ahead of the curve with the freshest news updates by exploring TodayFirstMagazine!